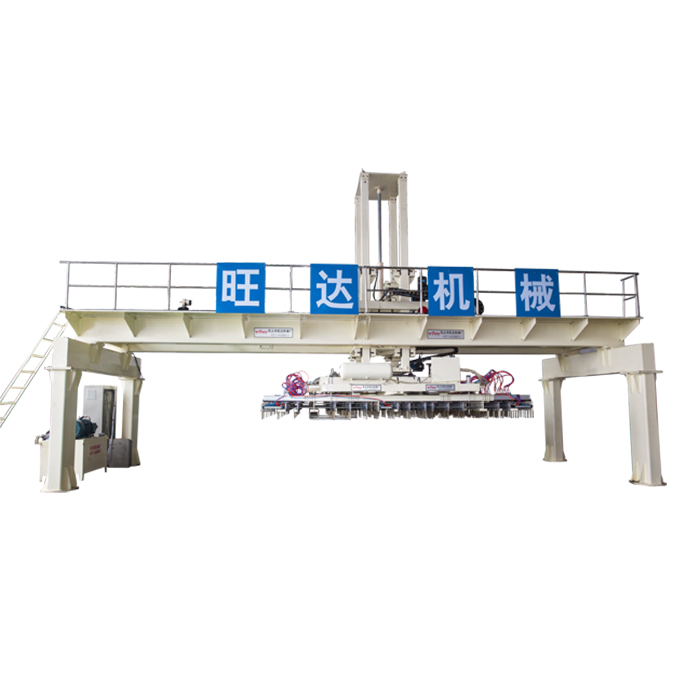

Automatic Pneumatic Brick Stacking Machine

Product Description

Automatic stacking machine & stacking robot are new brick automatic stacking, replace manual stacking way. It can greatly improve stacking efficiency and reduce labor cost. Depending on the size of the kiln, we should choose different types of stacking machine & stacking robot.

Advantage

1- Fast and efficient energy saving

2- Optimized high performance features make your production more efficient and accurate

3- Super suitable for a variety of brick types

Successful Projects

Product Parameters

| NO. | Type | Daily Production capacity | Main parameters |

| 1 |

3.3m One single fire kiln |

80000-100000

(size calculated by 24x11.5x5cm) |

Kiln inner width:3.3m

Kiln length: 132.6m Kiln car size:3.3mx3.42m |

| 2 |

3.6/3.7m One single fire kiln |

10000-150000

(size calculated by 24x11.5x5cm) |

Kiln inner width:3.6-3.7m

Kiln length: 141.2m Kiln car size:3.58mx3.84m |

| 3 |

3.6/3.7m One dry one fire kiln |

12000-180000

(size calculated by 24x11.5x5cm) |

Kiln inner width:3.6m

Kiln length: 111.6m Kiln car size:3.6mx3.72m |

| 4 |

3.6/3.7m Two dry two fire kilns |

25000-300000

(size calculated by 24x11.5x5cm) |

Kiln inner width:3.6m

Kiln length: 111.6m Kiln car size:3.6mx3.72m |

| 5 |

3.9m One single fire kiln |

130000-160000

(size calculated by 24x11.5x5cm) |

Kiln inner width:3.9m

Kiln length: 152.4m Kiln car size:3.9mx4.02m |

| ... |

... |

... | ... |

Operation Flow of Brick Setting Machine

When the transitional bed is fully occupied, the bricks are pushed to the brick board;

The Lift Cylinder controls the chunk clamps down to reach the bricks, then the lift cylinder lifts the clamped bricks to a certain height.

Chunk puts down the bricks on the tunnel kiln car.

The Parts of Automatic Brick-Setting Machine