Featured

-

Quality Inspection for Clay Brick Machine Supplier - Plate feeder for mining chemical cement building materials – Wangda

Introduction The plate feeder is the commonly used feeding equipment in the beneficiation plant. Working principle High strength die forging of bulldozer chain for traction, two chain bypass is installed on the head of a driven sprocket and body got behind a pair of tension wheel at the end of the closed loop, in every link of the two rows of chain on assembling the overlap each other, the transport of heavy structure slot as a continuous to carry material conveying line. The dead weight and... -

Hot sale Brick Making And Burning Machine - JKY40 Automatic Brick Making Machine – Wangda

Introduction of JKY40 Automatic Brick Making Machine Jky series double stage vacuum extruder is our factory designed and manufactured new brick manufacturing equipment through advanced domestic and international experience. The double stage vacuum extruder is mainly used for the raw materials of coal gangue, coal ash, shale and clay. It is the ideal equipment for producing all kinds of standard brick, hollow brick, irregular brick and perforated brick. Our brick machine has strong applicabili... -

Top Suppliers Automatic Clay Brick Making Machine - High Efficiency Energy Saving Automatic Tunnel Kiln – Wangda

Product Description Our company has tunnel kiln brick factory construction experience at home and abroad. The basic situation of the brick factory is as follows: 1. Raw materials: soft shale + coal gangue 2. Kiln body size :110mx23mx3.2m, inner width 3.6m; Two fire kilns and one dry kiln. 3. Daily capacity: 250,000-300,000 pieces/day (Chinese standard brick size 240x115x53mm) 4. Fuel for local factories: coal 5. Stacking method: by Automatic Brick Stacking Machine 6. Production line mach... -

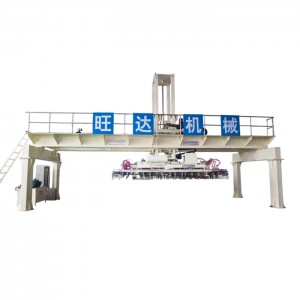

Factory supplied Making Machine Clay Brick - Automatic Pneumatic Brick Stacking Machine – Wangda

Product Description Automatic stacking machine & stacking robot are new brick automatic stacking, replace manual stacking way. It can greatly improve stacking efficiency and reduce labor cost. Depending on the size of the kiln, we should choose different types of stacking machine & stacking robot. Advantage 1- Fast and efficient energy saving 2- Optimized high performance features make your production more efficient and accurate 3- Super suitable for a variety of brick types... -

Well-designed Interlocking Block Making Machine - Hot sale cheap Box type feeder – Wangda

Main Use In the brick production line, the box feeder is the equipment used for uniform and quantitative feeding. By adjusting the height of the gate and the speed of the conveyor belt, the feeding amount of the raw materials is controlled, the mud and the internal combustion material are mixed in a proportion, and the larger soft mud can be broken. Technical Features 1. The box type feeder is composed of storage frame, drive, conveying device, easy operation and maintenance. During the worki... -

Cheap PriceList for Automatic Brick Factory - Good quality and durable industrial V-belt – Wangda

Brief Introduction The V-belt is also known as the triangular belt. It is the collective as a trapezoidal ring belt, mainly to increase the efficiency of the V belt, extend the service life of the V belt, and ensure the normal operation of the belt drive. V-shaped tape, referred to as V-belt or triangle belt, is a general name for the trapezoidal annular transmission belt, divided into special belt core V belt and ordinary V belt two categories. According to its section shape and size ca... -

Quality Inspection for Clay Brick Machine Supplier - WD4-10 Interlocking Brick Making Machine – Wangda

Introduction Interlock brick machine is the equipment to produce chain ecological slope protection bricks which protect soil and water by using stone powder, river sand, stone, water, fly ash and cement as raw materials. Wd4-10 automatic hydraulic interlocking clay brick and concrete brick making machine is suitable for the production of clay brick, clay brick, cement brick and interlocking brick. 1. Fully automatic clay cement brick machine. PLC controller. 2. It is equipped with a... -

Chinese Professional Bricks Manufacturing Machine - Belt conveyor with competitive price and wide use – Wangda

Introduction Belt conveyors, also known as belt conveyors, are widely used in household appliances, electronics, electrical appliances, machinery, tobacco, injection molding, post and telecommunications, printing, food and other industries, the assembly, testing, debugging, packaging and transportation of goods. In brick factory, belt conveyor is often used to transfer materials between different equipment, such as clay, coal and so on. Technical Parameters Belt width (mm) Conveyor len... -

Best quality Machine For Manufacturing Brick - Hoffman kiln for firing and drying clay bricks – Wangda

The Hoffmann kiln refers to a continuous kiln with an annular tunnel structure, divided into preheating, bonding, cooling along the length of the tunnel. When firing, the green body is fixed to one portion, sequentially add the fuel to the various locations of the tunnel, so that the flame is continuously moved forward, and the body is sequentially passed through three stages. The thermal efficiency is high, but the operating conditions are poor, used for firing bricks, watts, coarse ceramics... -

High definition Brick Making Machine South Africa - WD2-15 Interlocking ECO Brick Making Machine – Wangda

Product Description WD2-15 Hydraulic Interlocking Brick Making Machine is our newest clay and cement brick making machine.it is semi-automatic operation machine.its material feeding.mould pressing and mould lifting automatically ,you can chose diesel engine or motor for power supply. The most versatile of the market, for enable varied models of blocks, bricks and floors in only one equipment, without the need of buy another machine. It is hydraulic pressure,easy operation.about 4000-5000 Bric... -

Professional Design Clay Soil Brick Making Machine - High production capacity Double Shaft Mixer – Wangda

Introduction The Double Shaft Mixer Machine is used for grinding brick raw materials and mixing with water to get uniform mixed materials, which can further improve the performance of raw materials and greatly improve the appearance and molding rate of bricks. This product is suitable for clay, shale, gangue, fly ash and other extensive working materials. The double-shaft mixer uses the synchronous rotation of two symmetrical spiral shafts to add water and stir while conveying dry ash and oth... -

Well-designed Interlocking Block Making Machine - High Efficiency Energy Saving Automatic Tunnel Kiln – Wangda

Product Description Our company has tunnel kiln brick factory construction experience at home and abroad. The basic situation of the brick factory is as follows: 1. Raw materials: soft shale + coal gangue 2. Kiln body size :110mx23mx3.2m, inner width 3.6m; Two fire kilns and one dry kiln. 3. Daily capacity: 250,000-300,000 pieces/day (Chinese standard brick size 240x115x53mm) 4. Fuel for local factories: coal 5. Stacking method: by Automatic Brick Stacking Machine 6. Production line mach...