Featured

-

Best Price on Brick Machine Small - Buy JKY50 Red Fired Clay Brick Vacuum Extruder – Wangda

Application Wangda JKY50 double-stage vacuum extruder is an important machine in brick making equipment, which determines the quantity and quality of finished bricks. This JKY50 brick machine can be used to produce wet adobe bricks of any size required by the customer, and then through the cutting machine, the brick stacking machine, after sintering and drying in the kiln, the final bricks can be obtained as follows (solid or hollow bricks). Structure Wangda JKY50 brick machine structur... -

New Fashion Design for Small Brick Making Machine Price - Plate feeder for mining chemical cement building materials – Wangda

Introduction The plate feeder is the commonly used feeding equipment in the beneficiation plant. Working principle High strength die forging of bulldozer chain for traction, two chain bypass is installed on the head of a driven sprocket and body got behind a pair of tension wheel at the end of the closed loop, in every link of the two rows of chain on assembling the overlap each other, the transport of heavy structure slot as a continuous to carry material conveying line. The dead weight and... -

Chinese wholesale Clay Brick Machine - Best popular JKR35 Mud Soil Clay Brick Machine – Wangda

Brief Introduction Red brick machine, vacuum extruder, using a single extrusion principle, using a motor, through the axial pneumatic clutch through the reducer split drive superior mixing and lower extrusion part synchronous. Compact structure, energy saving effect is obvious. Vacuum brick machine is the most common brick machine equipment in the sintering brick factory, but also the most core machine in the whole brick production line. In the production line and box feeder, roller, double ... -

Chinese wholesale Clay Brick Machine - Hoffman kiln for firing and drying clay bricks – Wangda

The Hoffmann kiln refers to a continuous kiln with an annular tunnel structure, divided into preheating, bonding, cooling along the length of the tunnel. When firing, the green body is fixed to one portion, sequentially add the fuel to the various locations of the tunnel, so that the flame is continuously moved forward, and the body is sequentially passed through three stages. The thermal efficiency is high, but the operating conditions are poor, used for firing bricks, watts, coarse ceramics... -

Factory wholesale Brick Maker - JZ250 Clay Mud Soil Brick Extruder – Wangda

Product Description JZ250 High quality clay mud brick making machine can produce solid bricks of clay, such as 240×115×53(mm) Chinese Standard Clay Bricks. It consists of 4 parts, including the Feeding and Mixing Part, the Extruding Part, the Brick Strip Cutting Part, and the Adobe Brick Cutting Part. Its auxiliary equipment is the mixer. Its daily production is 15000 pieces. Its total power is 11 KW. This machine is suitable for small brick factory. The disadvantage is that the hollow brick ... -

2021 wholesale price Brick Machine - Good quality and durable industrial V-belt – Wangda

Brief Introduction The V-belt is also known as the triangular belt. It is the collective as a trapezoidal ring belt, mainly to increase the efficiency of the V belt, extend the service life of the V belt, and ensure the normal operation of the belt drive. V-shaped tape, referred to as V-belt or triangle belt, is a general name for the trapezoidal annular transmission belt, divided into special belt core V belt and ordinary V belt two categories. According to its section shape and size ca... -

Big Discount Clay Brick Machine Price - WD4-10 Interlocking Brick Making Machine – Wangda

Introduction Interlock brick machine is the equipment to produce chain ecological slope protection bricks which protect soil and water by using stone powder, river sand, stone, water, fly ash and cement as raw materials. Wd4-10 automatic hydraulic interlocking clay brick and concrete brick making machine is suitable for the production of clay brick, clay brick, cement brick and interlocking brick. 1. Fully automatic clay cement brick machine. PLC controller. 2. It is equipped with a... -

One of Hottest for Interlocking Bricks Machine - Good quality and durable industrial V-belt – Wangda

Brief Introduction The V-belt is also known as the triangular belt. It is the collective as a trapezoidal ring belt, mainly to increase the efficiency of the V belt, extend the service life of the V belt, and ensure the normal operation of the belt drive. V-shaped tape, referred to as V-belt or triangle belt, is a general name for the trapezoidal annular transmission belt, divided into special belt core V belt and ordinary V belt two categories. According to its section shape and size ca... -

professional factory for Hot Clay Brick Making Machine - JZ250 Clay Mud Soil Brick Extruder – Wangda

Product Description JZ250 High quality clay mud brick making machine can produce solid bricks of clay, such as 240×115×53(mm) Chinese Standard Clay Bricks. It consists of 4 parts, including the Feeding and Mixing Part, the Extruding Part, the Brick Strip Cutting Part, and the Adobe Brick Cutting Part. Its auxiliary equipment is the mixer. Its daily production is 15000 pieces. Its total power is 11 KW. This machine is suitable for small brick factory. The disadvantage is that the hollow brick ... -

Factory directly Clay Brick Making Machine Low Price - JZ250 Clay Mud Soil Brick Extruder – Wangda

Product Description JZ250 High quality clay mud brick making machine can produce solid bricks of clay, such as 240×115×53(mm) Chinese Standard Clay Bricks. It consists of 4 parts, including the Feeding and Mixing Part, the Extruding Part, the Brick Strip Cutting Part, and the Adobe Brick Cutting Part. Its auxiliary equipment is the mixer. Its daily production is 15000 pieces. Its total power is 11 KW. This machine is suitable for small brick factory. The disadvantage is that the hollow brick ... -

Low MOQ for Brick Machine Manufacturers - Plate feeder for mining chemical cement building materials – Wangda

Introduction The plate feeder is the commonly used feeding equipment in the beneficiation plant. Working principle High strength die forging of bulldozer chain for traction, two chain bypass is installed on the head of a driven sprocket and body got behind a pair of tension wheel at the end of the closed loop, in every link of the two rows of chain on assembling the overlap each other, the transport of heavy structure slot as a continuous to carry material conveying line. The dead weight and... -

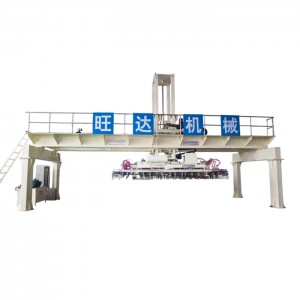

Factory directly supply Mud Brick Making Machine Price - Automatic Pneumatic Brick Stacking Machine – Wangda

Product Description Automatic stacking machine & stacking robot are new brick automatic stacking, replace manual stacking way. It can greatly improve stacking efficiency and reduce labor cost. Depending on the size of the kiln, we should choose different types of stacking machine & stacking robot. Advantage 1- Fast and efficient energy saving 2- Optimized high performance features make your production more efficient and accurate 3- Super suitable for a variety of brick types...