Free sample for Auto Brick Manufacturing Machinery - JZ250 Clay Mud Soil Brick Extruder – Wangda

Free sample for Auto Brick Manufacturing Machinery - JZ250 Clay Mud Soil Brick Extruder – Wangda Detail:

Product Description

JZ250 High quality clay mud brick making machine can produce solid bricks of clay, such as 240×115×53(mm) Chinese Standard Clay Bricks.

It consists of 4 parts, including the Feeding and Mixing Part, the Extruding Part, the Brick Strip Cutting Part, and the Adobe Brick Cutting Part.

Its auxiliary equipment is the mixer. Its daily production is 15000 pieces. Its total power is 11 KW.

This machine is suitable for small brick factory. The disadvantage is that the hollow brick can not be produced, the advantage is that the operation is very simple and the price is low.

1. This machine is suitable for making solid clay brick, red clay brick, red clay standard brick, red clay brick, etc. Different moulds can produce different bricks.

2. Materials are rich and easy to find, such as clay, shale, coal gangue, fly ash, etc. It was easy to set up a factory and start making bricks.

3. This machine has the advantages of high production efficiency, compact structure, reliable performance, convenient maintenance and stable operation without anchor bolts.

Technical Parameters

|

Type |

JZ250 |

|

The configuration of power(kw) |

11 |

|

Power Engine |

Electric or Diesel |

|

Products |

Solid Bricks |

|

Daily production |

15000 pcs /8 hours |

|

Dimention(mm) |

3000*1100*1300 |

|

Weight(kg) |

870 |

Application

JZ250 Clay brick machine is the smallest models brick extruders.

It is widely used in small family brick owners.Suitable for family workshops.

Also, its compact design makes machine operation very easily.

Characteristics

1. The automatic brick making machine has reasonable structure, compact structure, no need for anchor bolts, stable work and convenient installation.

2. The shaft and gear are made of high quality carbon steel and alloy steel. The key parts are treated by quenching and tempering to prolong the service life.

3. Screws are painted with wear-resistant metal.

4. All machines adopt screw pressure clutch (patent), high sensitivity, complete tripping.

5. The automatic brick-making machine adopts electric clutch, which is more convenient to operate.

6. The automatic brick making machine adopts copper support bearing and impregnation lubrication mode.

7. The reducer adopts hardened gear.

Packing details

1. Standard export packaging or according to customer requirements.

2. Use crane/forklift to load the machine into containers.

3. Fix the machines with wire to keep them stable.

4. Use the cork wood forbid collision

Shipping details

1.Lead time for mass production :within 3 days after received 30% down payment.

2.Delivery date:within 5 days after received balance payment.

How to Make bricks

Power System

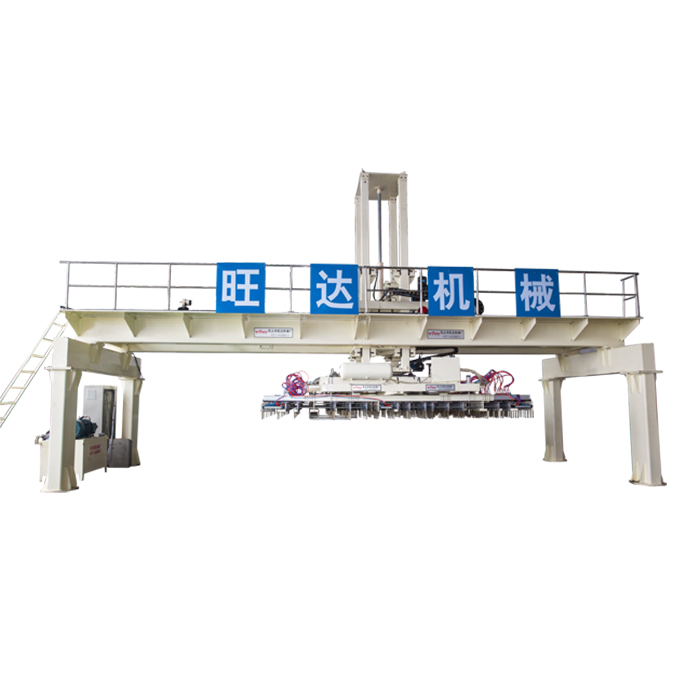

Product detail pictures:

Related Product Guide:

Reliable good quality and very good credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality 1st, purchaser supreme" for Free sample for Auto Brick Manufacturing Machinery - JZ250 Clay Mud Soil Brick Extruder – Wangda , The product will supply to all over the world, such as: Pakistan, Doha, Mexico, We hope we can establish long-term cooperation with all of the customers. And hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!