The tunnel kiln as one of the most advanced technology in the brick making field, so,if you want to build a brick factory, it is definitely good choice.

But,how to use the tunnel kiln to fire the brick ?

We will give you to explain in detail.

The tunnel kiln include the drying kiln and the firing kiln.

First, After the auto brick setting machine set the brick, the klin car send the brick to the drying kiln, in order to drying the brick. Drying kiln's temperature is about 100℃. And there is a chimney on the drying kiln, it is used to take out the moisture from the drying kiln.

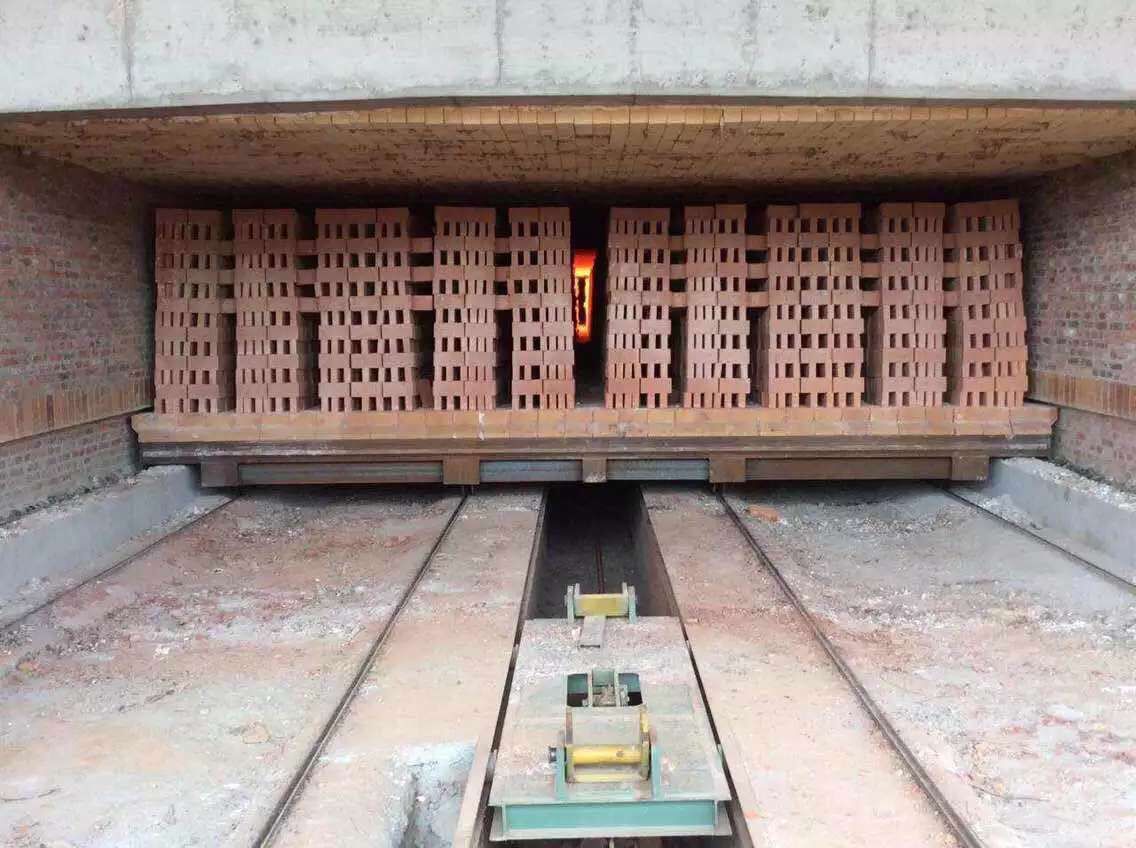

Second, the brick after drying, use the same way, use the klin car send the brick to the firing kiln.

The firing kiln include 4 stage.

The first stage : preheat stage.

The second stage : firing stage.

The third stage : heat preservation stage.

The fourth stage : cooling stage.

Now, if you want to build the tunnel kiln, we can offer the professional basic parameters of the kiln.

The tunnel kiln basic parameters:

| Wide within the kiln(m) | Height of the kiln (m) | Daily capacity (pcs) |

| 3.00-4.00 | 1.2-2.0 | ≥70,000 |

| 4.01-5.00 | 1.2-2.0 | ≥100,000 |

| 5.01-7.00 | 1.2-2.0 | ≥150,000 |

| >7.00 | 1.2-2.0 | ≥200,000 |

Post time: Aug-23-2021