One of Hottest for Interlocking Bricks Machine - Buy JKY50 Red Fired Clay Brick Vacuum Extruder – Wangda

One of Hottest for Interlocking Bricks Machine - Buy JKY50 Red Fired Clay Brick Vacuum Extruder – Wangda Detail:

Application

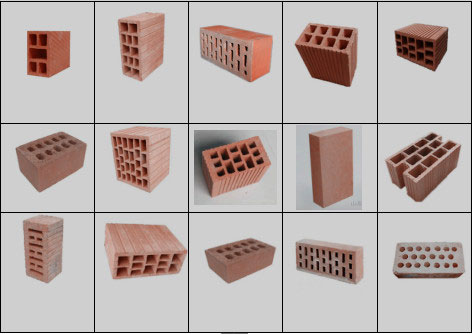

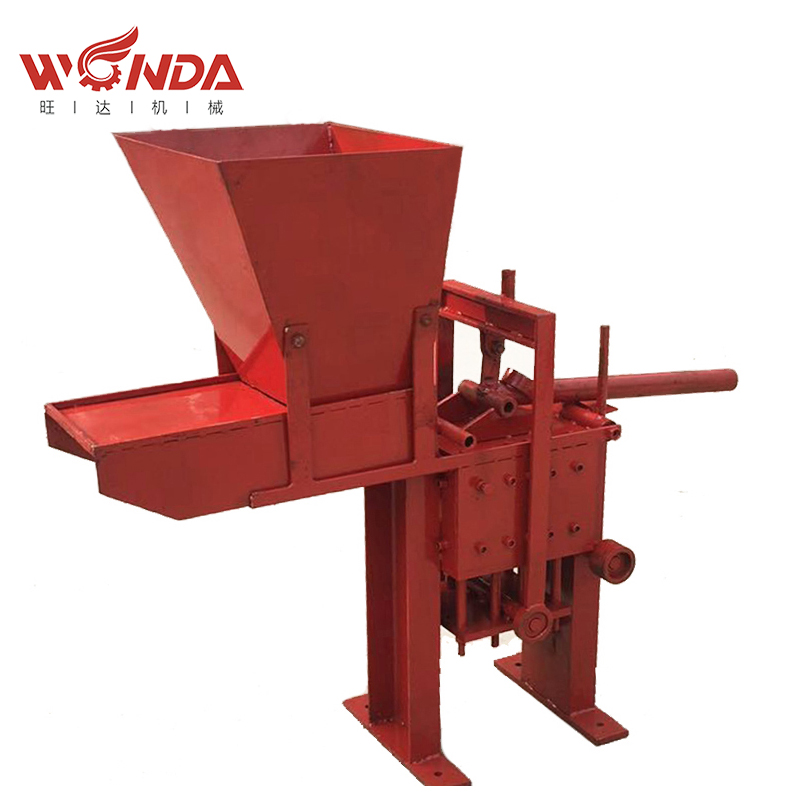

Wangda JKY50 double-stage vacuum extruder is an important machine in brick making equipment, which determines the quantity and quality of finished bricks. This JKY50 brick machine can be used to produce wet adobe bricks of any size required by the customer, and then through the cutting machine, the brick stacking machine, after sintering and drying in the kiln, the final bricks can be obtained as follows (solid or hollow bricks).

Structure

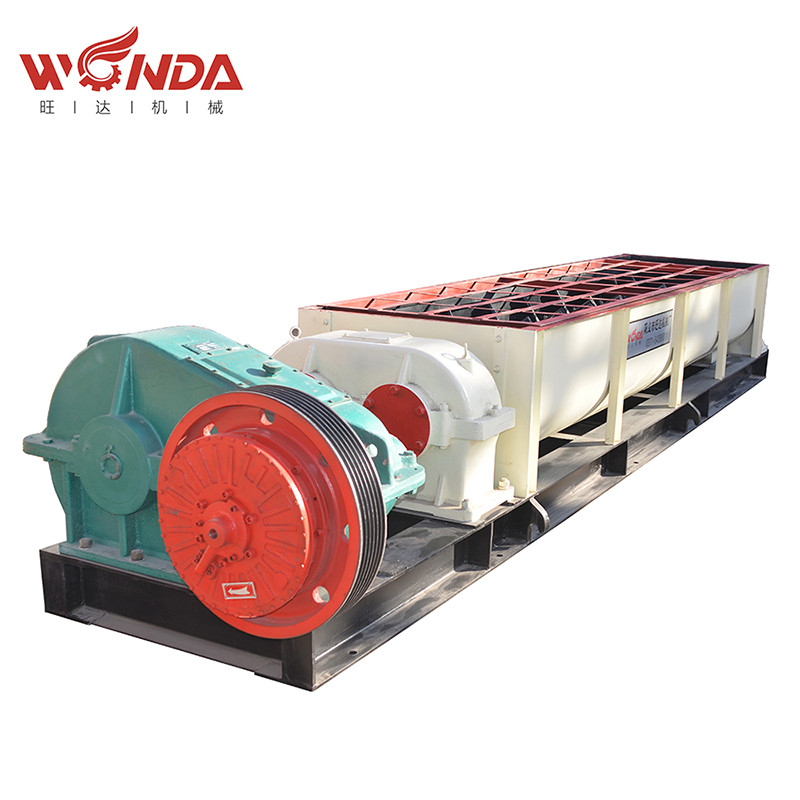

Wangda JKY50 brick machine structure can be divided into two parts, upper and lower part.

The upper part is the mixing and vacuum section including the mixing shaft and vacuum pump.

At the lower is the extrusion section containing the reamer, shaft, mud compression device and reducer.

The whole machine is made of all-steel welded construction, floating shaft and wear-proof bushing/lining.

Features

* Fully automatic brick machine, do not need manual operation to make bricks

* Higher capacity, 100,000-150,000 bricks / 8 hours

* Lower power consumption, saving power costs

* Easy to operate and maintain. Spare parts can be easily changed

* Longer service life, more than 15 years

According to the different production requirements of customers, Wangda machinery plant provides different models of brick machine -JKR30, JKR35, JZK40, JKB45, JKB50/45, JKY50 and JKY55, JKY60, JKY70, for your choice.

Technical Specifications for Wangda JKY series of Brick Machine

|

Model |

Production Capacity -brick/hour |

Allowable Pressure -MPa |

Power -kw |

Reamer diameter -mm |

|

JZK40 |

8000-10000 |

3.0 |

90 |

400 |

|

JKB45/45-3.5 |

10000-13000 |

3.5 |

55+160 |

450 |

|

JKB50/45-3.0 |

10000-14000 |

3.0 |

160 |

500/450 |

|

JKY50/50-3.5 |

12000-16000 |

3.5 |

55+160 |

500 |

|

JKY55/55-4.0 |

11000-25000 |

4.0 |

75+185 |

550 |

|

JKY60/60-4.0 |

18000-24000 |

4.0 |

90+250 |

600 |

|

JKY70/60-4.0 |

18000-24000 |

4.0 |

90+250 |

700/600 |

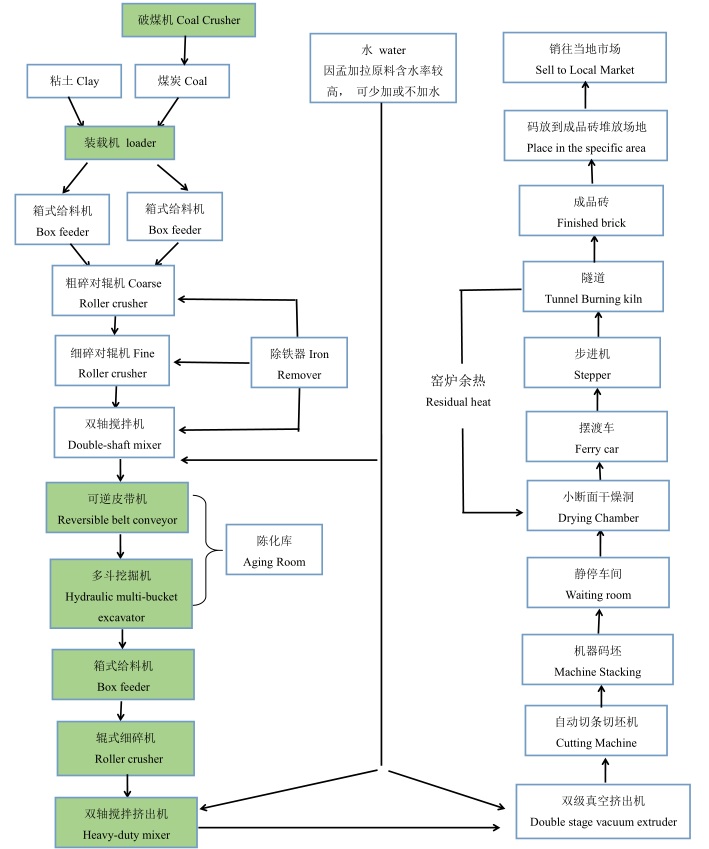

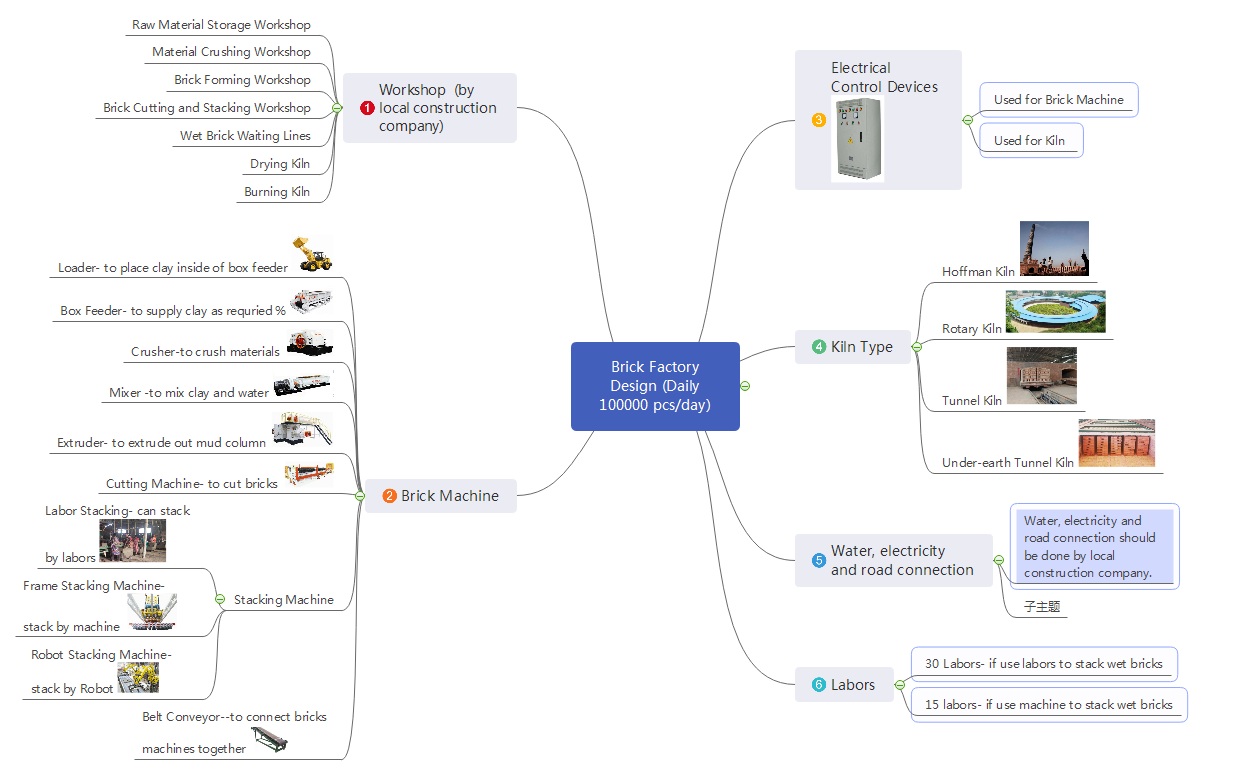

Technology Flow Chart of full automatic brick production line with tunnel kiln

Fully automatic production line with tunnel kiln normally adopts technology process below:

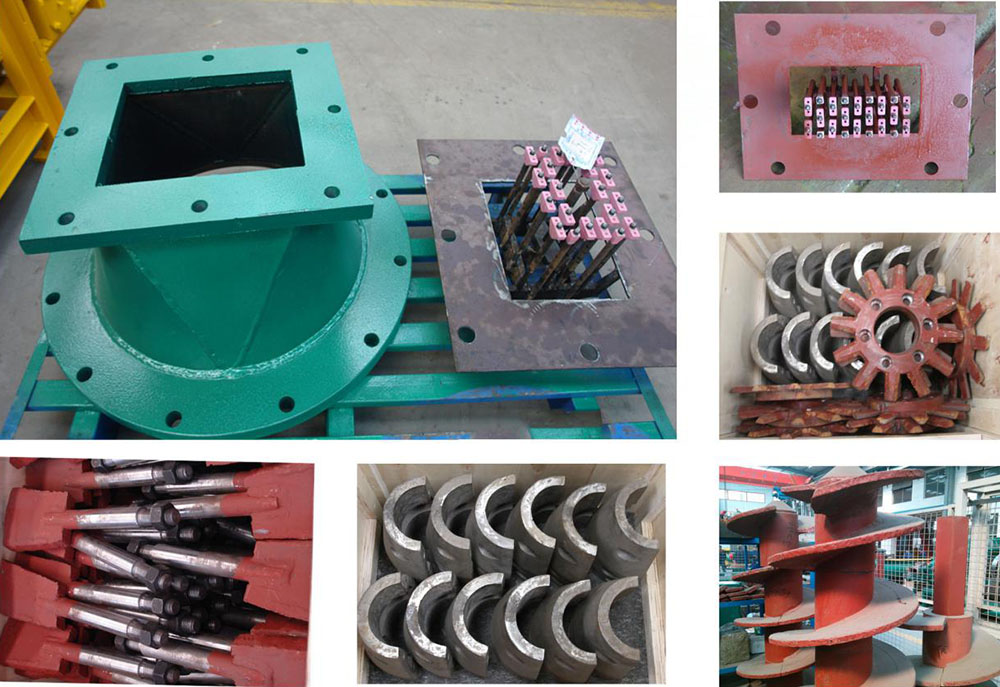

Spare Parts

Normally spare-parts need to change every three months.

If you choose to purchase our equipment, we will provide you with spare parts for one year.

We have enough stock, once you need, please feel free to contact us.

Basic information about the whole brick factory

Company Information

Gongyi Wangda Machinery Plant was established in 1987, already serves clients over 30 years. Our machines come with ISO9000 certificate, and confirmed as Brand Name Products in Henan Province.

We can:

-undertake turn-key project

-provide technology guidance before sales

-provide kiln design & construction

-supply fired brick machines & cement brick machines, and finished brick testing machines

-ensure in-time after-sales service

-design whole plant according to material type and client requirements.

Choose Wangda brick machine, choose a way to success !

Certificate

OUR CUSTOMERS

Packaging & Shipping

Contact Us

Whatsapp/Tel/Wechat/: 0086-15537175156

FAQ

1. Q: Are you a manufacturer?

A:Yes, we are a professional manufacturer of brick machines with experience of more than 30 years.

We are able to supply clay brick machines and cement block machines.

2. Q: What is the scope of your services?

A: – Raw material testing before setting up the plant

- Make complete design of the brick factory

-Supply brick/block machine and design burning kiln

-Supply Spare parts for the brick & block machinery

- Send engineers to help finish machine installation and commissioning

3. Q: What is your delivery time?

A: Normal delivery time is 20-35 days, larger orders take longer.

4. Q: What is the warranty period for the machine?

A: The warranty is 12 months from the date of delivery.

5. Q: What are your terms of payment?

A: We can accept TT or LC.

6. Q: How to solve any problems during production?

A: We offer a 24-hour online service to guide you through your problems. If the online service cannot help you, send the engineer as client’s request.

Product detail pictures:

Related Product Guide:

We have now a hugely efficient team to deal with inquiries from buyers. Our goal is "100% client gratification by our solution high-quality, rate & our team service" and take pleasure in a great popularity among clients. With several factories, we will provide a wide assortment of One of Hottest for Interlocking Bricks Machine - Buy JKY50 Red Fired Clay Brick Vacuum Extruder – Wangda , The product will supply to all over the world, such as: Seattle, Latvia, New Delhi, We've been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. Most people firmly believe we've the whole capacity to provide you happy solutions.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!