Renewable Design for Brick Making Machine Clay - JKY40 Automatic Brick Making Machine – Wangda

Renewable Design for Brick Making Machine Clay - JKY40 Automatic Brick Making Machine – Wangda Detail:

Introduction of JKY40 Automatic Brick Making Machine

Jky series double stage vacuum extruder is our factory designed and manufactured new brick manufacturing equipment through advanced domestic and international experience. The double stage vacuum extruder is mainly used for the raw materials of coal gangue, coal ash, shale and clay. It is the ideal equipment for producing all kinds of standard brick, hollow brick, irregular brick and perforated brick.

Our brick machine has strong applicability, compact structure, lower energy consumption and higher production capacity.

Transport: By sea

Packing: bare, fixed in container by wire

Main technical parameters of JKB50/45 Automatic Clay Brick Making Machine:

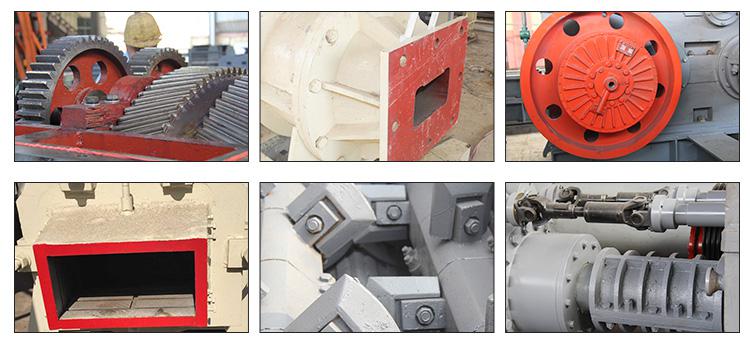

1. Welded by high-quality steel , solid and durable properties , reasonable structure , eliable performance.

2. Good tightness,high vacuum degree and extrusion pressure,low energy consumption , high efficiency.

3. Main shaft , gear and reamer are used heat treatment process ensuring the long service life.

4. Reasonable design , easy installation , upper and lower motor could be t-square or straight line type installation.

We have the model of JKY35, JKY40, JKY45, JKY50, JKY60, etc.

Different requirements apply to different models. If you have any questions, please feel free to contact me.After all, choosing the right machine is a key factor in productivity.

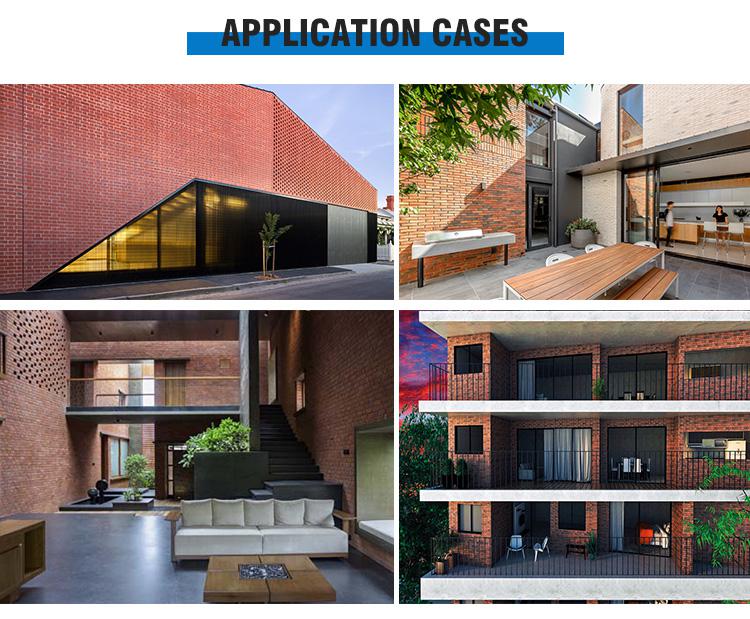

High Quality Vacuum Clay Brick Products

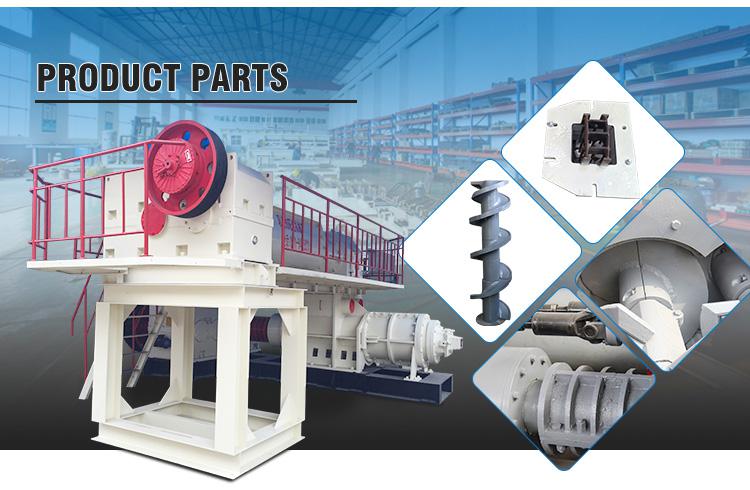

The Details of the JKY40 Vacuum Brick Machine

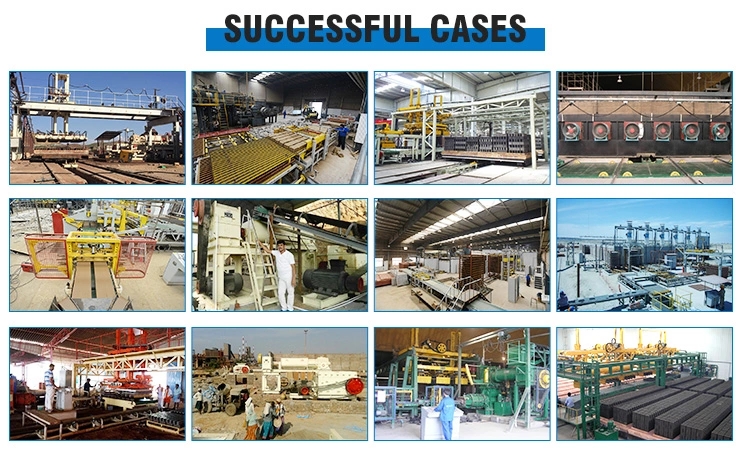

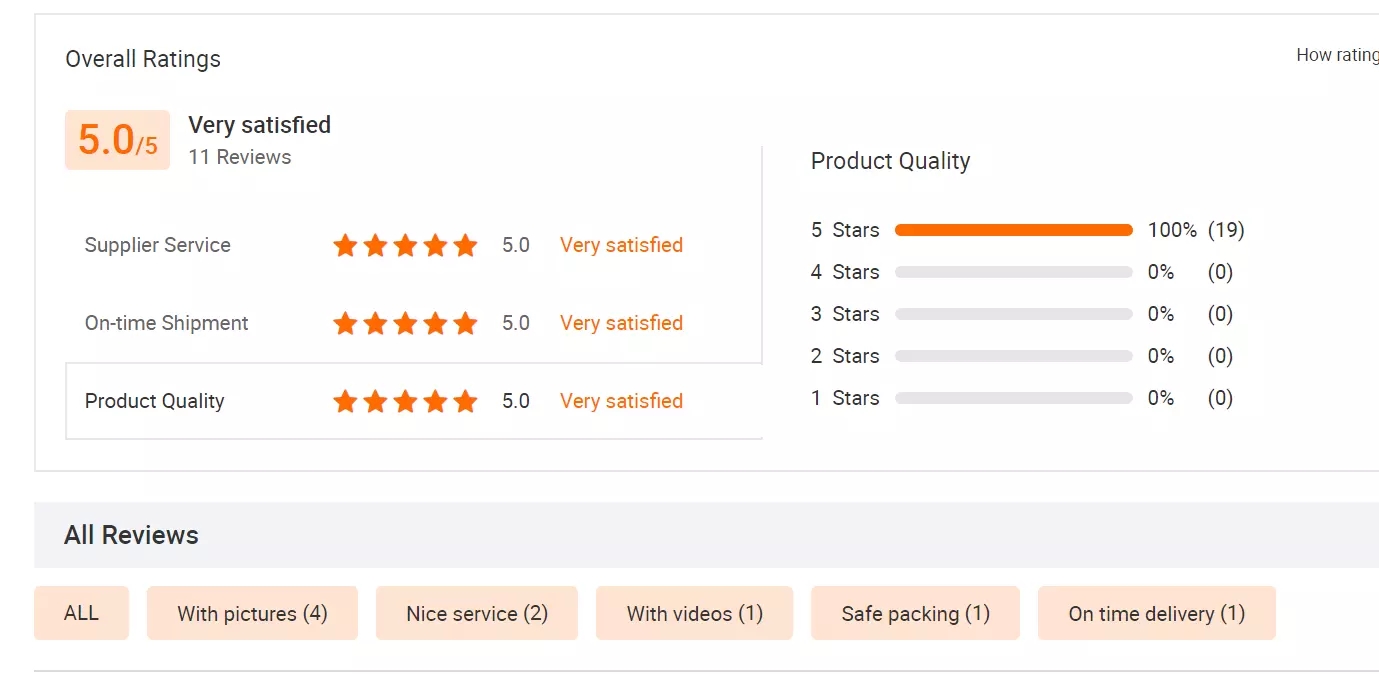

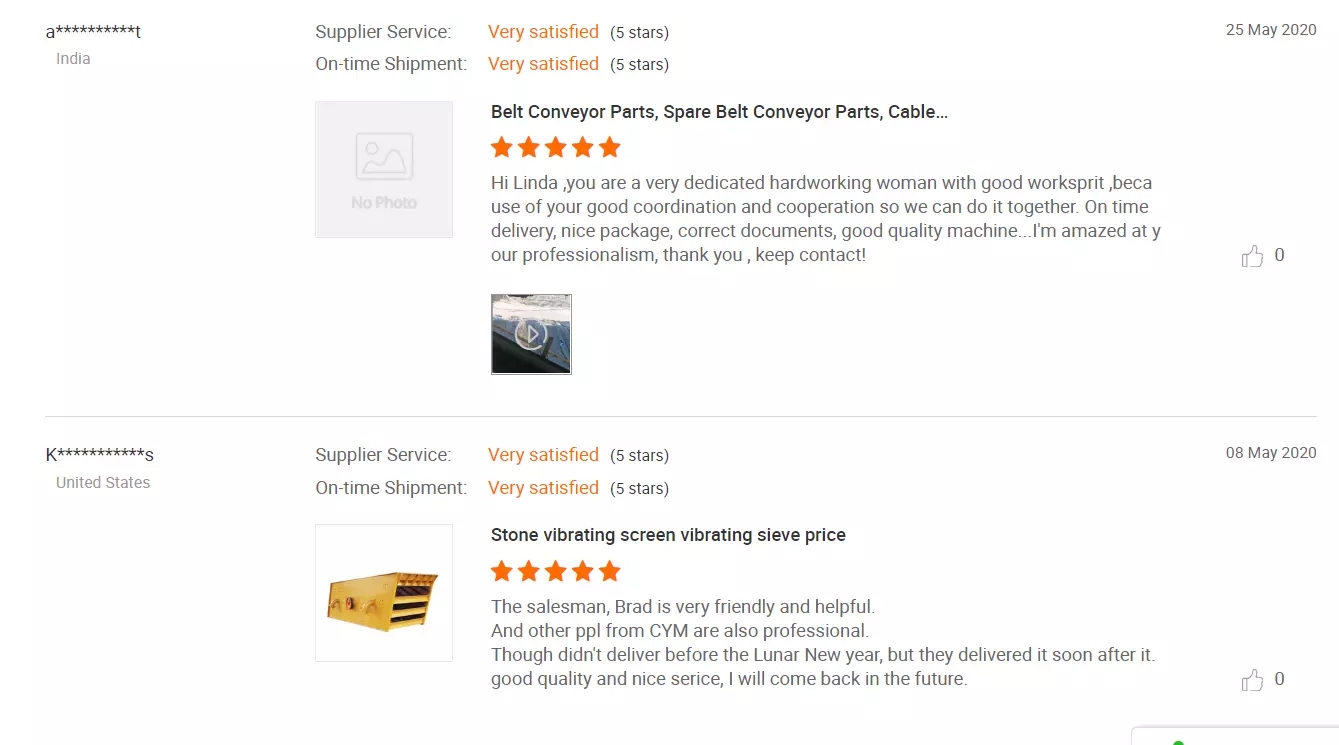

Clients’ feedback

We strive to provide customers with high quality mechanical products and 7X24 hours of service.

We have gained a good reputation with our customers over the past 30 years.

Check out the photos below for details.

FAQ

Ask: How could I set up a brick factory?

Answer: First, the raw material you use to make bricks, clay, mud, soil…

Second,what is the brick size in your market.

Last,what is your production capacity.

Ask: The warranty of the equipment?

Answer: 1 year excluding the wear part.Spare parts are recommended to keep at lease one year in case of emergency.

Ask: How can I use your machine to produce bricks?

Answer: We will send our engineer team to your place to design and help you to build the brick factory, and install our machines, at same time, we will train your workers until product the qualified products.

Company Information

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Renewable Design for Brick Making Machine Clay - JKY40 Automatic Brick Making Machine – Wangda , The product will supply to all over the world, such as: Lesotho, Cambodia, Lebanon, Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We have won a good reputation for outstanding customer service among our overseas customers. We will continue to try the best to offer you good quality products and the best service. We are looking forward to serving you.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.